- Deborah Shaffer Schnell, PE

The zero valent iron (ZVI) technology has been around for nearly 30 years, and is a preferred remediation tool for many regulators and experts. As such, it’s important for every environmental consultant to understand what it is and how it works.

If you’d like to dive in deeper and learn about the most suitable geology or site constraints that could affect a ZVI remediation remedy, watch our webinar on demand, 2019 Has Been a Good Year for ZVI Emplacement. All attendees will receive a certificate of completion and have the opportunity to ask questions.

FIRST, LET’S COVER THE MOST BASIC QUESTION: WHAT IS ZERO VALENT IRON EMPLACEMENT?

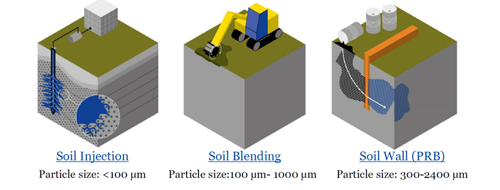

ZVI emplacement is an in situ amendment for the treatment of chlorinated solvents. It was the first in trenched barrier application nearly 30 years ago, and now is also injected and blended with contaminated substances.

Not all ZVI are the same. They differ by size, iron content, porosity, hydraulic conductivity, surface area, reactivity, and longevity. Based on site characteristics, chlorinated solvent contaminant concentrations, and remediation objectives, the ZVI can be optimized for a particular site. In many applications, a combined ZVI (abiotic) and carbon substrate/bioaugmentation culture (biotic) mixture is used as a very aggressive in situ approach to achieve remediation expectations faster and limit the production of vinyl chloride break down products.

HOW DOES ZVI EMPLACEMENT WORK?

ZVI is a catalyst that, in the 1970s and 1980s, was found to encourage the breakdown of chlorinated compounds in aqueous solutions. This is what makes it an excellent technology for the remediation of contaminated groundwater.

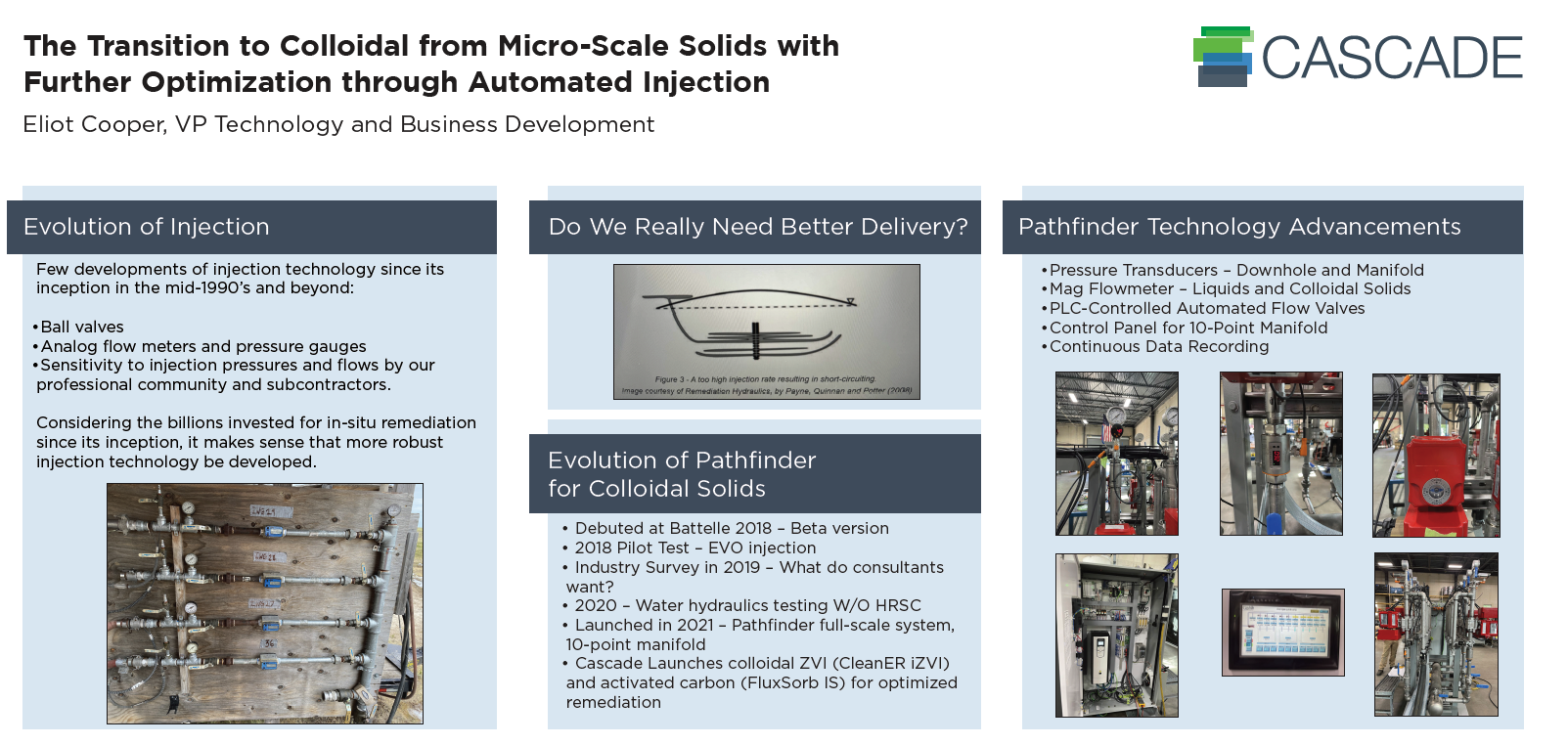

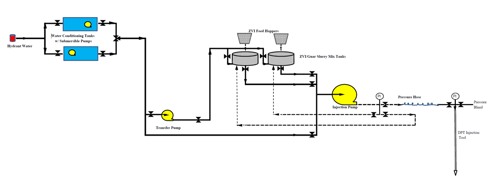

Pneumatic emplacement of ZVI begins when fractures are created using high pressure nitrogen. Then, using hydraulic injection, ZVI amendments can be added to the fractured zone. Typically, this is done using straddle packers in open boreholes, through sonic casing, or direct push technology (DPT).

A typical process flow for hydraulic emplacement of ZVI.

ZVIs can also be emplaced using other methods, such as trenchless permeable reactive barriers (PRB), which use casing dilation. Multiple injections of ZVI—which is carried in food-grade cross-linked guar—are utilized to ensure the barrier wall is thick enough.

Another method for using ZVI is soil mixing. Soil mixing is performed either with augers for deep applications, or with custom-made rotary mixers for shallow applications that are generally less than 25 feet. It is best applied where injection approaches can’t achieve the contact necessary for contaminant treatment or stabilization. Ideal sites include fine grained soils, and high concentrations of contaminants.

HOW DO YOU CHOOSE THE BEST ZVI EMPLACEMENT METHOD FOR YOUR PROJECT SITE?

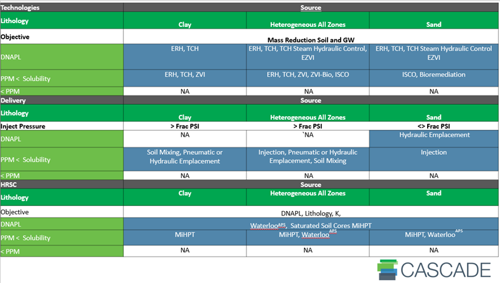

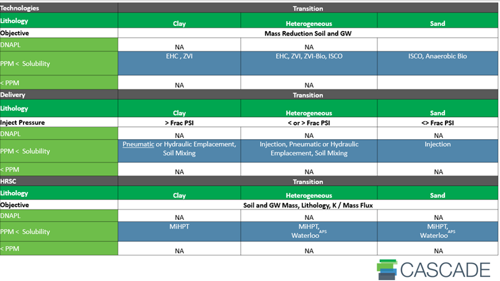

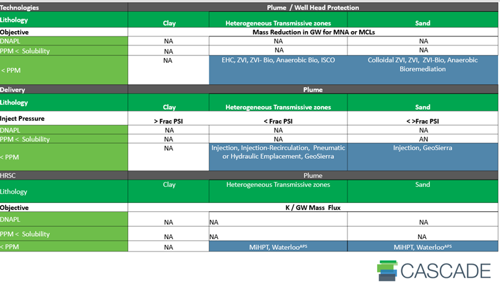

Every site is different, and choosing the right ZVI emplacement method can make a huge difference in achieving project goals. When selecting, one must consider the lithology, the contaminant(s), and source v. plume. The charts below highlights when a ZVI delivery is recommended, as well as what delivery approach would be most suitable.

SOURCE ZONE

TRANSITION ZONE

PLUME ZONE

COST-EFFECTIVE TECHNOLOGY

ZVI is an effective and cost-efficient technology for groundwater remediation, but it requires careful planning and expert application to ensure success.

ZVI REMEDIATION RESOURCES

- Not All ZVI is Created Equal: How the Manufacturing Process Can Impact Project Outcomes

- What You Need to Know About Distributing Colloidal ZVI in High K Transmissive Zones

- What is Colloidal iZVI™?

If you’d like to learn more about ZVI emplacement, see some case studies, and speak to renowned fracturing experts, register our on-demand webinar, 2019 Has Been a Good Year for ZVI Emplacement.

Ready to use ZVI for an upcoming remediation project? Request a quote.

Categories

- Site Remediation

- Drilling

- Careers

- Cascade Chemistries

- Safety

- Site Characterization

- Thermal

- Rotary

- Sustainability

- In Situ Stabilizaton

- High Resolution Site Characterization

- Injection

- Sonic Drilling

- Automated injection

- corporate sustainability

- case studies

- in situ thermal remediation

- Cascade Drilling

- Over Water Drilling

- In Situ Stabilization (ISS)

- ISS

- Environmental Remediation