SITE BACKGROUND

TerraTherm, a Cascade Company executed an in situ thermal remediation (ISTR) project at this former dry cleaning facility, which is currently owned by the State of California. Electrical Resistance Heating (ERH) was chosen as the treatment technology best suited to meet site remediation goals. This high profile project was funded by the State and performed in downtown Sacramento, CA. The location of project and fact that it was one of first thermal projects funded by the State of California DGS resulted in significant level of project scrutiny and interest from State legislature.

CONTAMINANTS OF CONCERN (COCs)

COCs consisted primarily of PCE and its associated daughter products, including TCE, cis-1,2-dichloroethene (cis-1,2-DCE). Stoddard Solvent and other petroleum hydrocarbon compounds were also present within the thermal treatment volume.

THERMAL OBJECTIVES

Remediation goals varied by contaminant species and treated media. The cleanup targets for soil ranged from a 95% to 98% reduction in COC concentrations. In groundwater the goals varied from 98% to 99.9% reduction.

DESIGN AND INSTALLATION

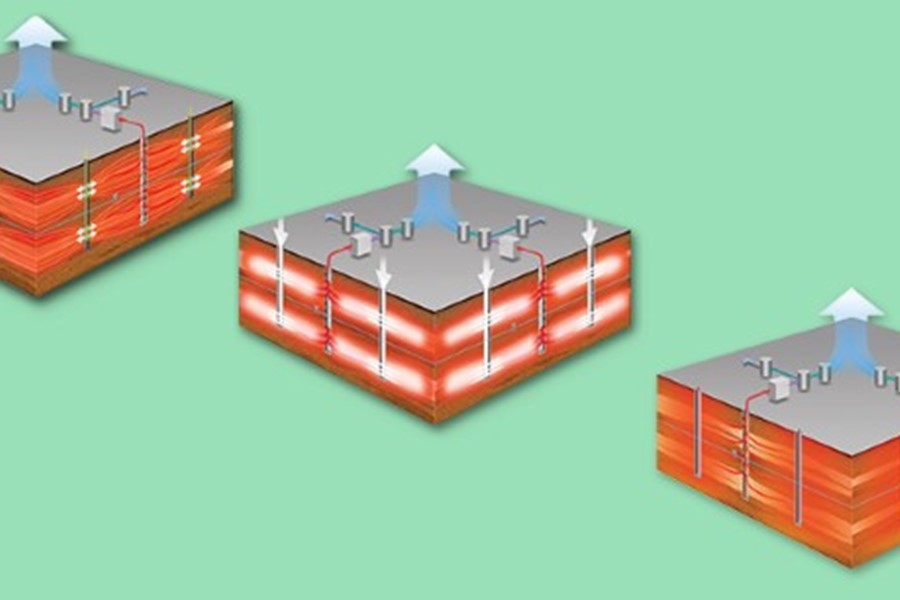

The treatment area was approximately 1,600 square feet, with heating targeting the depth interval of 5 to 45 feet below grade surface (ft bgs). TerraTherm’s design utilized 15 evenly spaced vertical electrodes to treat a contaminated soil volume of 2,370 cubic yards. Each electrode contained an upper “pipe” heating element which featured a co-located vapor recovery well and a lower “plate” heating element which targeted heating below the groundwater table.

The upper heating element treated vadose zone soil from 5 to 25 ft bgs while the lower heating element treated impacted soil in the saturated zone from 27 to 45 ft bgs. The co-located recovery wells in the upper elements removed steam and contaminant vapors generated during ERH operations in both heating intervals.

This electrode design allowed for greater flexibility in the application of power to vadose zone and the saturated zone. Electrodes were constructed in 12 inch diameter borings spaced on 15 ft centers. Half inch water supply lines were installed in each of the upper (vadose zone) electrode elements. These “drip tubes” were connected to an automated water feed system which maintained the moisture level around the vadose zone electrode elements in order to ensure optimum energy transfer from the electrodes into the impacted soil matrix.

TerraTherm measured subsurface temperatures at four temperature monitoring points (TMPs) installed within 6 inch borings. Each TMP contained nine thermocouples placed at 5 foot depth intervals from surface to the bottom of heating. Readings from these 36 thermocouples were used to build a real-time subsurface heating profile for the site. Due to the project location in a dense urban setting within three blocks of the capitol building, the State of California requested that, to the extent possible, all vapor extraction piping, electrical cables, and water supply lines be installed in below grade trenches. In addition, once installation of the system was complete, the State required that the site-specific ERH system configuration be certified by a Nationally Accredited/Recognized Third Party Certification Laboratory. Intertek Group, PLC provided the required third party system inspection and certification.