What is Cascade Chemistries?

What is Cascade Chemistries?

Cascade Chemistries™ is a new line of amendments for in situ groundwater remediation, designed to help you reach site closure faster and cost-effectively.

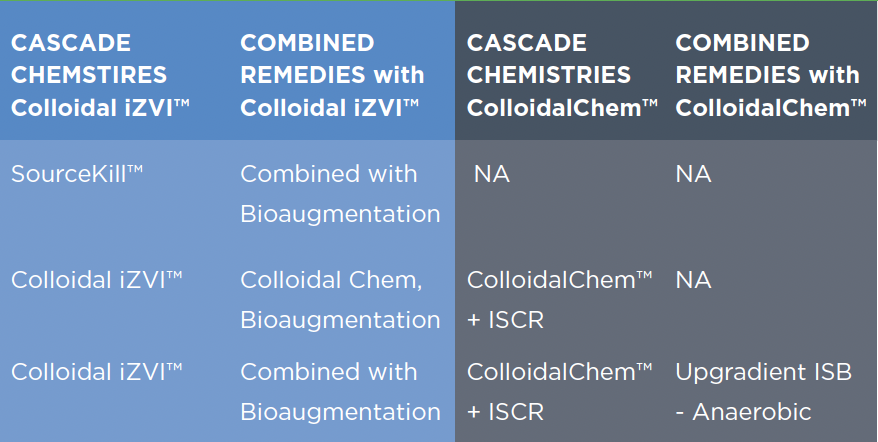

ColloidalChem™ is a group of high mobility and low pressure, injectable colloidal activated carbon products designed to target difficult-to-treat contaminants like chlorinated volatile organic compounds (CVOCs), per and polyfluoroalkyl substances (PFAS), benzene/toluene/ethylbenzene/xylenes (BTEX), and other pollutants.

Colloidal iZVI™ is a colloidal (5 um) injectable zero valent iron (iZVI) designed specifically for chlorinated solvent remediation, but can also be applied to hazardous metals, herbicides, and pesticides. Colloidal iZVI primarily targets contaminants in transmissive zones down gradient of the source or in barrier applications. It’s also effective in remediating less concentrated source areas by treating contaminants through chemical reduction.

Colloidal S-iZVI™ is a colloidal (5 μm) injectable zero valent iron (iZVI) with sulfidated iron particle surfaces, specifically designed for chlorinated solvent remediation. When iron undergoes sulfidation, it forms mackinawite (iron sulfide, FeS) deposits on the surface of the zero valent iron particles. This sulfidated coating enhances the reactivity and longevity of the iron particles, making them more effective in degrading contaminants.

SourceKill™ is an emulsified zero valent iron for chlorinated solvent source remediation, including DNAPL It is manufactured exclusively for Cascade, the first licensee of this NASA patent for DNAPL remediation at Cape Canaveral. SourceKill uses chemical reduction to primarily target known or suspected DNAPL source zones.

The Pathfinder is a fully-automated injection system designed to deliver liquid amendments and colloidal solids like ZVI and activated carbon more effectively in transmissive zones. It addresses the issue of distribution by providing an automated, fine tune-able system that takes human variables out of the equation, while Cascade Chemistries products tackle the problem of persistent contact with contaminants in the subsurface.

Cascade Chemistries Services

Cascade’s proprietary chemistries are applied to contaminated sites by Cascade’s remediation experts, who have decades of experience in the integration of high resolution characterization design optimization (HRDO) with injection and fracturing. We provide consultants with the data needed to identify where and how to apply remedies for best results, implement the approved remediation design, and partner with the client to monitor for optimization opportunities.

This means you get an integrated solution that is cost effective, reduces risk, and is designed to provide an excellent return on your remediation investment.

To provide this integrated approach, we utilize multiple existing services in conjunction with the new chemistries, including but not necessarily limited to:

- HRDO

- 3D visualized targeted remediation plans

- Hydraulic testing of wells or DPT screens

- Design optimization testing (DOT) prior to full scale remediation

- Manifolding automated injection of liquid and colloidal amendments

- Pneumatic & hydraulic emplacement

- Downhole pulsing for delivery into highly heterogeneous and moderate K zones

- Post remediation troubleshooting

Leveraging technologies, experience, and expertise together ensures the ideal placement of the chemistries to ensure contaminant contact in transmissive (higher K) and/or storage (lower K) zones. This means an expedited schedule to closure and reduced project costs.

Cascade Chemistries are the latest addition to our existing suite of services designed to support every stage of the project lifecycle. We offer an integrated turnkey solution to provide optimized results, but still offer other chemistries, amendments, and services individually as needed.