What is Bioremediation?

Provides longer in situ persistence than chemical oxidants allowing for extended residence time for treatment ...

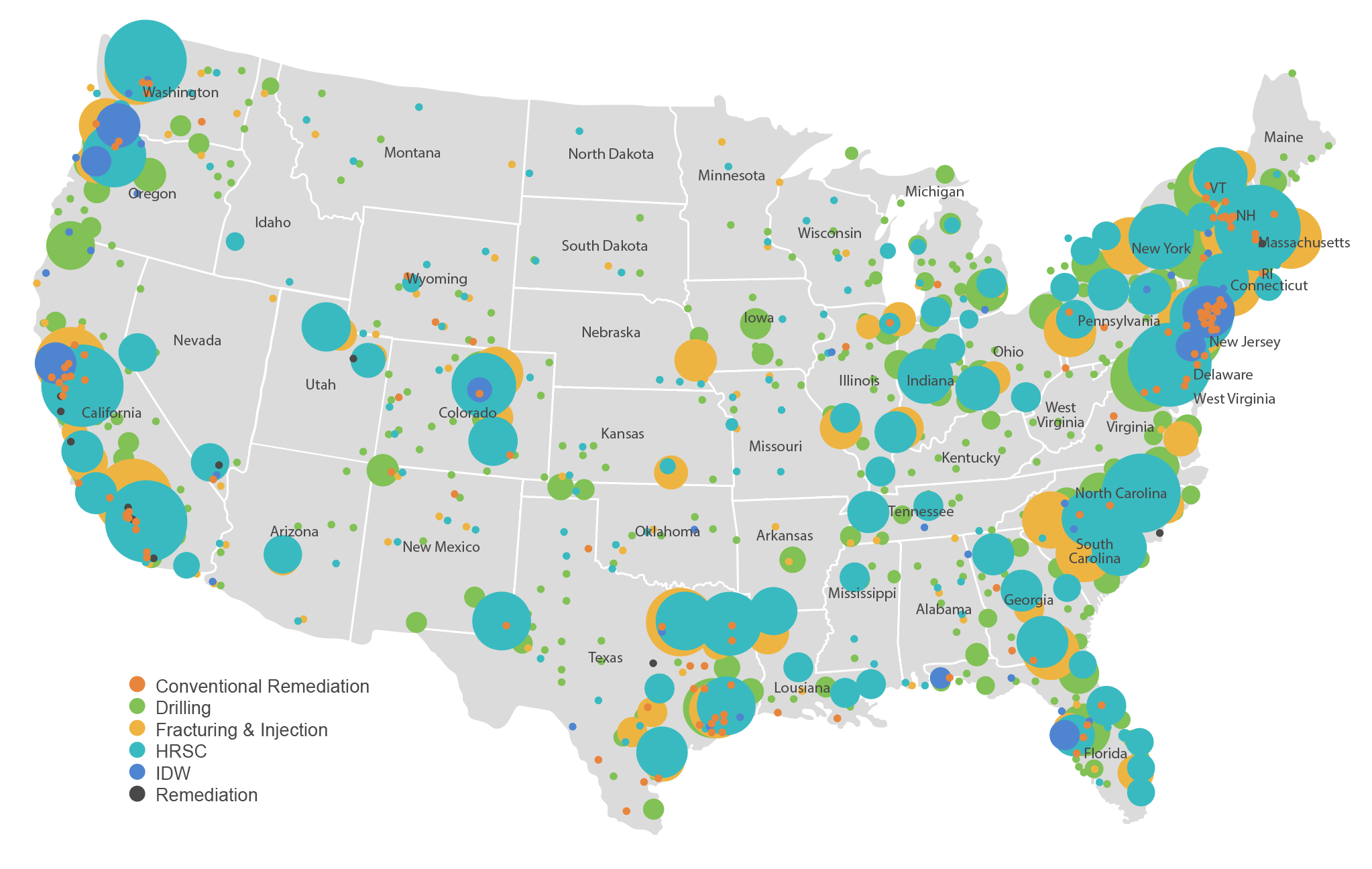

Optimize your project outcome with support from industry experts who have solved complex remediation challenges across the US for decades.

With so many remediation options available, choosing the best technologies and approach can be daunting. We know your client’s priorities impact your decision, whether they’re most concerned with…

Whatever your project priorities, we can help. Cascade Remediation Services™ provides a range of options regarding price and timeframe, and our experts can support you in optimizing for your project’s specific goals.

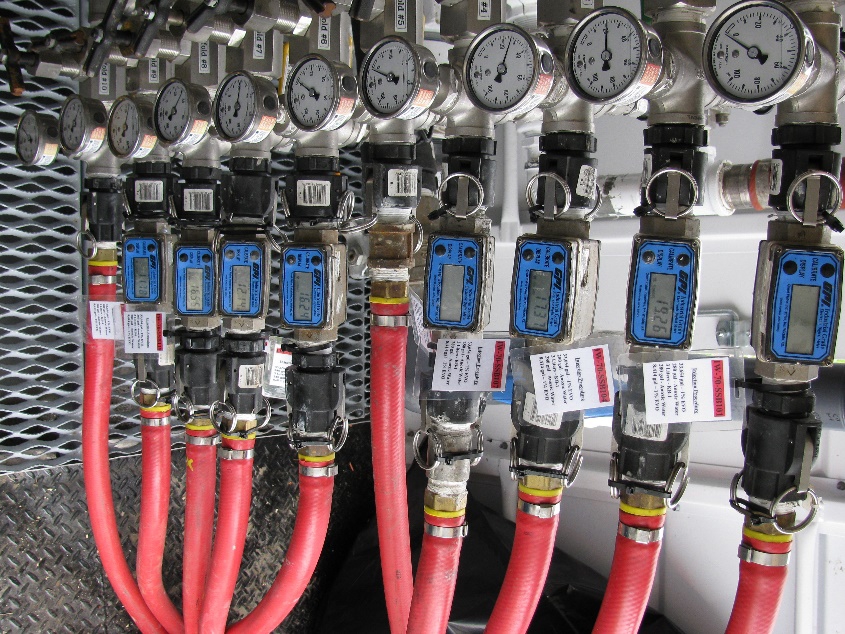

Check out our remediation technologies below. Not sure what you need? Drop us a line and let us know about your project—one of our experts will be happy to follow up.