Best Practices and Lessons Learned Toward Designing ISCR, ISCO, and Bioremediation

By: CascadeOver the last month we’ve hosted a few webinars on environmental remediation and the best practices in implementing the various technologies and methods used in site remediation. In this post, we’ll provide you a breakdown of Part 4 of our remediation webinar series covering the best practices when it comes to designing ISCR, ISCO, and Bioremediation methodologies for groundwater remediation.

The past decade has seen rapid progress in groundwater remediation along with an increasing understanding of the capabilities and limitations of the technologies used in remediation. When it comes to groundwater remediation, Cascade Environmental has experience at hundreds of sites across the country with various subsurface geologic and hydrogeologic conditions and contaminant concentrations. From that experience we’ve developed a number of workable strategies for getting the absolute most out of In Situ Chemical Reduction (ISCR), In Situ Chemical Oxidation (ISCO) and bioremediation.

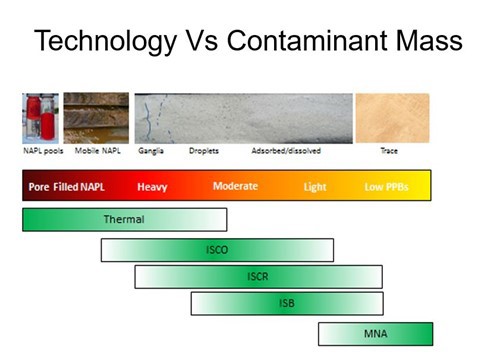

Typically, the nature and concentration of the contaminant of concern (COC) as well as the subsurface hydrogeology dictates which remedy is best suited for the site. However,experience has shown that different technologies are needed at different times and locations, and that combining technologies may improve overall remedy performance. The current options for remediating source areas and plumes in situ include bioremediation, chemical oxidation, chemical reduction, and thermal treatment.

The current state of the science, based on Cascade's robust portfolio of experience, is covered below.

ISCO (In Situ Chemical Oxidation)

The ISCO process involves injecting a massive supply of thermodynamically powerful electron acceptors into the subsurface. Commonly used substrates are permanganate, hydrogen peroxide, and activated sodium persulfate. ISCO is attractive because it provides rapid in situ destruction, but rebound and incomplete treatment have been consistent problems and ISCO can be only marginally effective on chloroethene source treatment.

Rebound has been attributed to:

- Reactants that are short-lived and thus do not reach contaminants in low permeability zones.

- Sorbed contaminants that may be released following oxidation of natural organic matter.

- Delivery challenges – where the reagent fails to come in contact with a substantial fraction of the mass.

Based on our implementation experience and review of performance monitoring data, we’ve found that ISCO performance can be improved by:

- Considering NAPL or mass sorbed to soils that can require multiple applications to liberate and treat.

- Consider hydraulics and ISCO kinetics in the radius of influence design estimates (e.g. injection volumes too low).

- Use high resolution site characterization (HRSC) and don’t rely just on data derived from monitoring wells data which are insufficient to define target intervals

- Don’t inject through wells at highly heterogeneous sites.

- Paying closer attention to field parameters such as distribution, pressure, flows, tooling, and injection approach.

Since ISCO is a relatively short-lived treatment technology, effective design assumptions must address how to dose for mass in the sorbed or DNAPL phases that is not readily available for treatment unless in the dissolved phase. Therefore, the design best practices for ISCO should account for the eventual transition of mass bound up in soil and DNAPL to the dissolved phase. The design phase should not initially overdose by assuming this mass is all readily available for treatment.

It is recommended to treat all the dissolved phase plus a percentage of sorbed or DNAPL mass over multiple events. For example, twice the dissolved phase concentration can be targeted as a way to compensate for the dissolution of sorbed or DNAPL mass into the dissolved phase. To expedite DNAPL and sorbed mass treatment over equilibrium rates one can inject surfactants, heat the subsurface, or recirculate reagents to increase the residence time of the oxidants within the dissolved phase.

ISCR (In Situ Chemical Reduction)

ISCR refers to the transferring of electrons to contaminants from reduced metals or reduced minerals. A Permeable Reactive Barrier (PRB) remedy constructed using a trenched or emplaced ZVI (“iron wall”) is an example of ISCR where the chemical reaction occurs on the surface of ZVI particles as impacted groundwater flows through the wall.

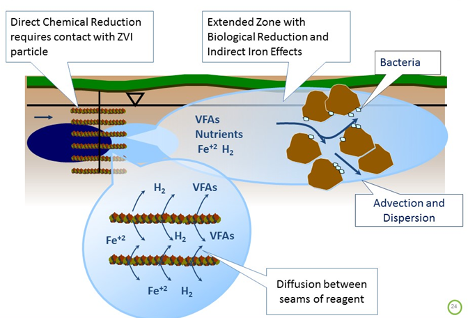

Many types/forms of injectable ISCR products are currently available, containing a more fine-grain ZVI (micro), ferrous iron and/or reduced minerals. Advanced ISCR reagents take advantage of the fact that fermentation of organic carbon in proximity to iron or iron-bearing minerals increases both reactivity and longevity of the iron component (alkaline/acid balance).

COMBINING CARBON DONOR AND ZVI

The advancement of including an organic carbon donor with micro-scale ZVI has expanded the range of ISCR applicability such that it can simultaneously treat metals, can be sequentially combined with ISCO, and facilitate post-treatment progression to MNA.

ISCR technology is flexible as a variety of ZVI, organic carbon substrates, and related additives can be mixed to customize the reagent to site-specific requirements. The capabilities of biogenically formed iron and sulfide minerals are now well known.

EMPLACEMENT OF ZVI

Emplacement of the technology is critical to accomplishing required contact. For ISCR, pneumatic or hydraulic emplacement is required to ensure contact between the reagent and the impacted media. Dosing rates/volumes are optimized based on pump pressure versus flow rate capabilities.

The best practices we’ve put together for pneumatic and hydraulic emplacement of ISCR reagents include the following guidelines:

- Emplace at greater than 10 feet below ground surface to minimize daylighting and enhance contact.

- Distribute reagent at high injection rates to maximize lateral distribution after fracture initiation with nitrogen, water, or soluble substrate.

- Utilize multiple lines of evidence to verify distribution, (e.g., pressure monitoring wells, points of compliance wells, EC logging, tilt meters).

- Stagger locations and vertical intervals and overlap areas of influence.

- Don’t skip intervals or reallocate amendments.

- Use directional tools versus radial as needed for better targeting in desired directions or underneath structures.

Engineered ISCR using ZVI in PRBs is a proven plume treatment technology. The microscale ZVI used for these barriers can be effectively distributed during injections and requires pneumatic or hydraulic emplacement technologies. The combination of ZVI (abiotic) with electron donors (biotic) offers the potential for rapid chemical degradation of the most accessible contaminants, combined with the longer-lasting bioremediation. The effects of ZVI on biochemistry and indigenous microbial populations appear minimal and may result in sustained reductions in oxidation reduction potential (ORP) that can enhance subsequent anaerobic biodegradation.

Bioremediation

Anaerobic biostimulation is the modification of the environment to stimulate existing bacteria capable of bioremediation of chlorinated solvents at low Eh levels. Anaerobic biostimulation occurs by adding one of the following to groundwater:

- Electron Donors - i.e. Lactate, EVO, lecithin, cellulose, lactose

- Nutrients - i.e. nitrogen, phosphorous, potassium

- Bioaugmentation - the introduction of a group of natural microbial strains to achieve bioremediation.

This method is most appropriate for plume areas where COC concentrations tend to be more dilute and in transmissive zones.

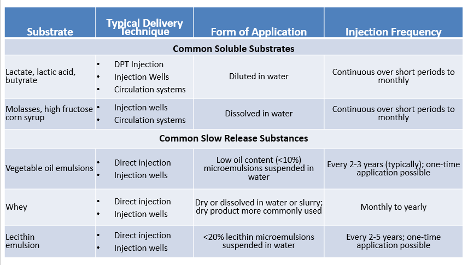

ELECTRON DONOR SELECTION

Electron Donor Selection is critical since all do not release hydrogen at the same rate, are not transported through the aquifer at the same rates, and do not have the same electron donor capacity. They are available in soluble and slow release forms, and can be combined both temporally and spatially. Factors to consider in donor selection include:

- Contaminant distribution and hydrogeology

- Required persistence/longevity

- Delivery approach

- Size for distribution by advection

- Synergy with bioaugmentation cultures

- Impacts on groundwater pH

Loading Rate. The appropriate amount must be distributed in the subsurface to develop optimal geochemical and redox conditions for anaerobic processes without creating adverse conditions. The goal is to achieve uniform distribution within four dimensions, including space and time, and design factors including target demands, residence time, injection volume. All to achieve desired ROI, substrate concentration in solution, and frequency of injections.

The best practice is to use conditioned treatment-area groundwater for substrate dilution or chase water. Groundwater should be extracted, conditioned to a strongly reducing state, and blended with substrate and a bioaugmentation culture in a batch tank. This approach:

- Minimizes plume displacement

- Maintains treatment zone geochemistry

- Utilizes indigenous microbial cultures to condition water

- Quickly establishes optimal conditions in the target aquifer to rapidly develop robust dechlorinating microbial culture

There are a number of ways of monitoring the efficacy of your ISCR, ISCO, and bioremediation designs. Ultimately, when it comes to using these methodologies for groundwater remediation, the simplest, most effective solutions are typically the way to go. For more information on bioremediation and other environmental remediation methodologies, visit our site and read about Cascade’s services and technologies.