How to Choose the Best Thermal Remediation Heating Technology for Your Site

By: John LaChanceOnce you’ve determined that a thermal remedy may be a good fit for your project site, it seems like the hard decisions should be over. Ah, if only it were that easy! There are three thermal heating technologies available—thermal conduction heating (TCH), electrical resistance heating (ERH) and steam enhanced extraction (SEE)—and they are all very different in how they address contaminants. While it might be fun to use a dart board, there are three major considerations when choosing a thermal heating technology, and I’ll cover them today in this blog post.

If you’d like a deeper dive and the chance to ask questions, join me tomorrow when I’m hosting a webinar titled ERH vs. TCH: How to Choose Your Thermal Remediation Technology (and Why). I’ll share real-life examples, detailed breakdowns, and cost comparisons to help you understand what you’re getting into with either technology.

What contaminants are you dealing with?

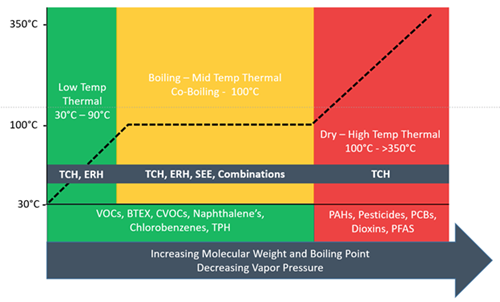

The type of contaminant can determine which thermal heating technology will work best. Volatile organic compounds (VOCs) and chlorinated volatile organic compounds (CVOCs) can be treated at 100° C, whereas semi-volatile organic compounds (SVOCs) such as PFAS, PCBs and PAHs require temperatures that are much higher (think 250-350° C). Meanwhile, some contaminants of concern (COCs) can be effectively remediated using low temperature approaches—meaning those that stay below 100° C—and provide enhanced biodegradation (BTEX) and hydrolysis.

If the contaminant on your site can be treated at or around 100° C, then any of the three heating technologies may be applicable depending on site conditions. However, TCH is the only option when you get to higher temperatures.

What is the geology of your project site?

The geology of your site can impact not only the technology you use, but also the way it’s designed and implemented. There are a few questions you need to be able to answer in order to choose the right heating technology:

- How variable and complex is the lithology?

- Is the site underlain by uniform sands, or is there a clay unit with interbedded sand seams?

- What is the soil resistivity of the site, and how much does it vary across the site and with depth?

- Does bedrock need to be treated too? If so, what type of rock is it (e.g., sedimentary, metamorphic, or igneous)?

In general, sites with highly variable resistivity may be more effectively treated using TCH, whereas sites with relatively uniform geologies can be treated with either TCH or ERH. For most bedrock settings, TCH will be the preferred technology due to the very low electrical resistivity of the rock matrix and associated limited and poor heating.

What kind of groundwater flow is present?

Thermal remediation can be effectively performed both above and below the water table. However, if the groundwater flux rate is too high, then heating may not be practical or uniform. The good news is that high groundwater flux is an indication of high permeability, which means combining SEE with either TCH or ERH may be a solution to effective heating.

Using a combination of technologies such as ERH or TCH and SEE allows us to effectively heat the entire site and ensure the remedial goals are achieved.

Theoretically, you can use ERH at a site with any soil resistivity, but the reality is that sites with very low (e.g., <1 ohm•m) or very high (e.g., >1,000 ohm•m) resistivity will be challenging to heat using ERH. Low resistivity sites will require high current cables, power control systems, field transformers, breakers and power distribution panels, etc., which can add substantial cost and complexity. Sites with high resistivity will require high voltage equipment with the proper safety rating and employee training.

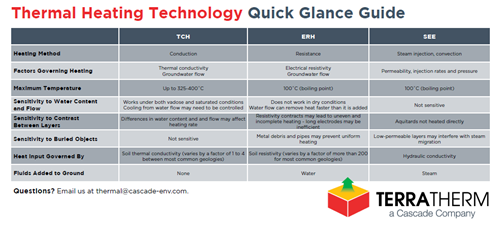

This is a lot to keep in mind, especially if you’re new to utilizing thermal technology. That’s why I put together this visual “cheat sheet”—it provides a quick glance summary of some of the characteristics of the various heating technologies and their applicability to various COCs.

There’s a lot to consider when choosing your thermal technology, but hopefully this gives you a foundation for making such a critical decision. If you need guidance, feel free to connect with me or another member of the TerraTherm, a Cascade Company team—we offer all three technologies and can help you make the right choice.

If you have additional questions, I invite you to register for tomorrow’s webinar. If you can’t make it, register anyway and you’ll be emailed a link to the recording so you can watch when you have time.

ABOUT THE AUTHOR

John LaChance

Vice President, Technology

[email protected]

John LaChance is the Vice President of Technology at TerraTherm, a Cascade Company. In his 30+ year career in the remediation industry, he’s worked on a range of project sites, including chemical manufacturing plants, gas stations, oil refineries, railroads, former MGP sites, solvent recycling facilities, grain and feed storage centers, and landfills. Most of these sites have focused on the assessment and cleanup of chlorinated solvents and other recalcitrant chemicals.

Those projects have taken him all over the world, to sites in Brazil, China, Australia, and several European countries. As an international expert on in situ thermal remediation (ISTR), John has led the charge for the development of innovative heating technologies, including identifying sustainable energy and geothermal techniques that can optimize thermal remedies with a smaller environmental footprint.

In his current role, John helps clients select thermal technologies that will meet regulatory requirements, eliminate liability, and enable the resale or reuse of their property. Having designed and implemented more than 50 in situ thermal remedies addressing a range of contaminants, John brings a wealth of technical and strategic insight to every project. His clients can rely on him and his team to safely achieve remedial targets on budget and on schedule.