Balancing Cost, Safety, and Quality: A Look at Auger vs. Sonic Drilling

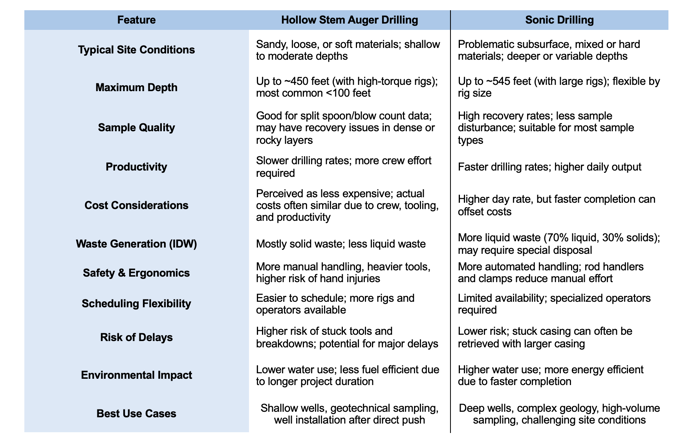

By: Shawn MillerChoosing the right drilling technology is one of the most important decisions in any site investigation or remediation project. The method you select can directly influence your schedule, sample quality, safety performance, and overall cost. While hollow stem auger drilling and sonic drilling are both well-established technologies, understanding their differences can help you select the most efficient and cost-effective option for your next site.

Understanding Each Method

Hollow stem auger drilling has been a cornerstone of geotechnical and environmental work for decades. It’s often selected for shallow projects or unconsolidated materials such as sands and silts. The auger acts as both the drilling tool and temporary casing, allowing for continuous sampling or well installation.

Sonic drilling, on the other hand, uses high-frequency mechanical vibration to advance a core barrel and casing through the subsurface. It’s highly adaptable and can penetrate a wide range of lithologies, from loose fill to dense glacial till and even weathered rock. With the right setup, sonic rigs can reach depths exceeding 500 feet while maintaining excellent sample recovery.

At first glance, auger drilling may appear to be the more economical choice. However, from an operator’s perspective, it costs just as much to run an auger rig as it does a sonic rig. The perceived savings are often a false cost comparison.

Cost and Productivity Considerations

Project cost is often the driving factor when comparing drilling methods. While daily rates for sonic rigs may be higher, their productivity can significantly offset the price difference. On a site requiring multiple borings or deep wells, that efficiency translates into shorter field time, lower labor costs, and faster data delivery. These benefits can often outweigh the higher daily rate.

Another consideration is investigation derived waste (IDW). Auger drilling typically generates more solid cuttings but little liquid waste, while sonic drilling produces a higher percentage of water mixed with fines. Because liquid waste can be classified as hazardous and require specialized disposal, waste management costs should always be factored into project planning.

Safety and Ergonomic Factors

When it comes to field safety, equipment design plays a major role. Traditional auger rigs require significant manual handling lifting heavy auger flights, connecting bolts, and maneuvering tooling that can exceed 100 pounds per section.

Sonic rigs, in contrast, are designed with assisted-lift systems, automated rod handlers, and hydraulic clamps that reduce manual lifting and hand-tooling risks. Drilling with augers is a physically involved approach, whereas with sonic, you’re still engaged, but much less exposed to those ergonomic hazards.

Beyond physical strain, sonic rigs also minimize the risk of hole-stopping events such as stuck tooling or equipment loss. Auger strings are more prone to refusal in dense layers or cobbles, which can lead to costly retrieval efforts and schedule delays. Sonic rigs are not immune to challenges, but they typically recover faster and continue drilling with fewer interruptions.

Depth, Lithology, and Sampling Quality

Depth capacity and formation type are often deciding factors in choosing between auger and sonic.

- Auger rigs are best suited for unconsolidated, soft materials and shallow depths—typically less than 300 feet.

- Sonic rigs excel in variable and challenging formations, maintaining sample integrity even through dense clays, gravels, and fill.

Each method can produce high-quality samples, but their strengths differ. Auger methods are well-suited for collecting split-spoon samples and measuring Standard Penetration Test (SPT) blow counts. Sonic cores, by comparison, offer continuous, undisturbed samples ideal for lithologic logging and geochemical analysis.

From experience, anything achievable with an auger rig can also be accomplished with a sonic rig, and often with added capabilities. The real distinction lies in the level of difficulty encountered when drilling through various subsurface conditions.

Regional and Project-Specific Trends

Across the U.S., auger drilling remains common for geotechnical sampling and shallow environmental work. However, many regions are transitioning to sonic as the preferred method for deeper or more complex investigations.

The trend is less about abandoning augers and more about right-sizing the method to the geology, project goals, and available budget. For instance, augers still play a valuable role in setting wells after direct push refusal or widening boreholes for installations completed with other methods.

Partnering for the Right Approach

Selecting the most effective drilling technology requires more than comparing day rates. It requires collaboration with experienced field professionals who understand how equipment, subsurface conditions, and project objectives intersect.

Cascade’s teams take a consultative approach to every project. By assessing site conditions, sampling needs, and waste management factors early, we help clients avoid costly delays and achieve the highest quality data possible. Whether your site calls for hollow stem auger, sonic, or a combination of both, our technical experts are here to help you make the best choice for your goals, timeline, and budget.

About the Author

Shawn Miller

Operations Manager

Aquifer, Drilling & Testing

[email protected]

Shawn Miller is an Operations Manager at Aquifer Drilling & Testing with over 28 years of experience in the industry. He has coordinated a wide variety of drilling projects across the northeastern US.