In Situ Bio-enhanced Thermal Remediation - Part 2

By: CascadeLast week we posted Part 1 of our Breakdown of the different technologies used for In Situ Bio-enhanced Thermal Remediation. If you’re looking for more info, make sure you download the webinar which provides in-depth details into the various technologies as well as the pros and cons of each.

For now, we’ll continue with the breakdown. This post is part 2 of our webinar breakdown, covering the different combined remedies for In-Situ Bio-enhanced Thermal Remediation.

We will start with the concept of biodegradation, with a brief look into how this concept plays out in chlorinated solvent biodegredation and reductive dechlorination. Next, we will talk about some of the approaches you can take to combine in situ thermal projects with bio applications, and some tools to help make monitoring and planning easier.

WHAT IS BIODEGRADATION?

BACKGROUND AND BASIC THEORY

There are three general biodegradation processes, all three of which may be found during the ISTR process:

- Aerobic metabolism (primary substrate) - where microorganisms consume the contaminant as their primary source of energy (food).

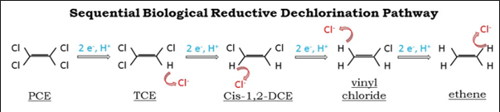

- Reductive Dechlorination (Anaerobic) Dichloroeleimination– where the contaminant is consumed in the transfer of electrons (energy) through respiration (breathing). In chlorinated solvent degradation can be referred to as halorespiration dehalorespiration which refers to the use of halogenated compounds as terminal electron acceptors in anaerobic respiration.

- Aerobic Co-metabolism (Dechlorination ) - where biodegradation occurs as a reaction between the contaminant and an enzyme produced during an unrelated reaction. For fuel hydrocarbons, the aerobic process is dominant.

CHLORINATED SOLVENT BIODEGRADATION

Full degradation of chlorinated solvent plumes often requires all three processes, as the co-metabolism step responsible for the breakdown of vinyl chloride requires an anaerobic step followed by an aerobic step

Aerobic metabolism depends on both the compounds being remediated and the temperature, pH, and salinity of the subsurface. In the absence of oxygen (an anaerobic site), microorganisms often use chlorinated compounds to facilitate respiration via an electron transfer processes. The most common anaerobic process for degrading chlorinated compounds is the electron transfer process called reductive dechlorination. Hydrogen atoms are sequentially substituted for a chlorine atom in the contaminant molecules.

Reductive Dechlorination

Variety of halorespiring bacteria are responsible for anaerobic reductive dechlorination:

- Dehalococcoides (DHC) - Only known bacteria capable of complete dechlorination of PCE /TCE to ethene. Several studies suggest that a threshold of less than about 10,000 cells/mL warrant the assumption that dechlorination of DCE and VC will NOT proceed at useful rates.

- Dehalobacter (DHB) - Known to degrade PCE and TCE through dechlorination to cis-DCE. This species effectively utilizes chlorinated ethanes (TCA and DCA isomers) in dechlorination reactions.

- Dehalogenimonas (DHG) – This bug can complete the dichloroelimination of 1,2-DCA and 1,1,2-TCA. Additionally, studies out there that have identified some strains of this bug capable of reductive dechlorination of trans-1,2-DCE and VC.

- Desulfitobacterium (DSB) - Capable of dechlorination of PCE and TCE to cis-DCE.

- Dehalobium chlorocoercia (DECO) - Capable of reductive dechlorination of chlorobenzenes and PCE/TCE to a mixture of Cis and tans-1,2-DCE.

Desulfurimonas (DSM) – Able to complete dechlorination of PCE and TCE to cis-DCE , typically using acetate as the electron donor in that reaction.

How does ISTR treatment tie together with the concept of biodegradation?

During traditional applications of ISTR, temperatures of 100°C or higher are reached throughout a treatment volume. And, while these high temperatures would seemingly limit biodegradation and sterilize microbial populations, plenty of evidence suggests that not only do ISTR projects not “sterilize” microbial populations from a site, but more moderate heating (i.e. 35°C) not only accelerates dissolution/desorption but will also enhance biotic degradation. Many populations involved in dechlorination reactions survive, recolonize and flourish at ISTR sites as temperatures begin to cool to more modest conditions.

For petroleum hydrocarbons, BTEX biodegradation has been shown to triple from 10 to 20°C and petroleum hydrocarbon biodegradation rates have been shown to peak between 30 and 40°C. A typical profile of petroleum contamination is a complex mixture of a range of compounds, or functional groups, with a range of chemical and physical properties, and degradability. Microbial populations of petroleum contaminant degraders are also diverse and variegated.

For the biodegradation of chlorinated solvents, many studies indicate that optimal temperatures for both maximum bacteria population growth as well as biodegradation rates peak at around 30 to 35°C, especially for species involved in dechlorination reactions. Many studies also suggest that at either lower or higher temperature ranges degradation trajectories stall out at some intermediary stage. For instance, at temperatures of either 20°C or 40°C, the degradation reaction stalls at the cis-DCE step in the sequence. Still, current research show that once temperatures reach (50 to 60°C) dechlorination reactions stop occurring all together.

What Does This Combination Look Like for a Project?

So putting this theme of heat enhanced biodegradation into actual implementation, there have three categories of projects that combine in situ thermal remediation with some component of heat enhanced biodegradation.

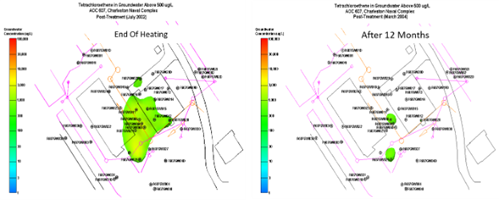

- Bio-Polishing – Utilizing residual heat energy from completed ISTR to “polish” off the source area contamination through enhanced biodegradation. This can be used to further reduce final groundwater concentrations from low concentrations to near ND levels. It can be supplemented with electron donor injection (lactate EOS or HRC) as well as bioaugmentation following ISTR treatment during the cooling period as the Site approaches those favorable temperature ranges hovering around 30C. Maximum degradation will occur at temperatures around 25 to 35⁰C, but elevated degradation will occur down to ambient conditions. Effective thermal technologies used in this option are ERH, TCH, and SEE.

- Low-Temp Heat Enhanced Bio Application – Deploy an ISTR system with the operational strategy of achieving 30 to 35 ⁰C temperatures throughout subsurface, maximizing biodegradation reaction rates while increasing free product extraction (if exists) and increasing hydrolysis reactions through thermally catalyzed hydrolysis reactions. Similarly this approach can be further supplemented with electron donor injections (lactate etc), and bioaugmentation injections of DHC cultures as needed. ERH or TCH would work in this application, however heat generation/propagation mechanism inherent to ERH may also lend itself to this application as well.

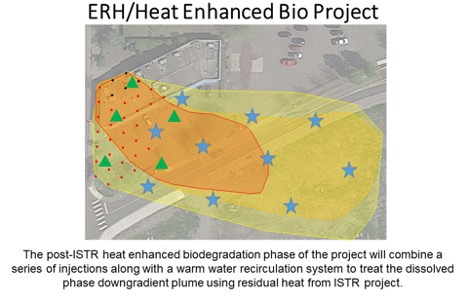

- ISTR Source- Heat Enhanced Biodegradation of Downgradient Plume - This approach involves implementing an ISTR system with the overall operational strategy of achieving 100⁰C temperatures in the source area, maximizing mass removal from source using volatilization, steam entrainment and vapor phase removal mechanisms. Following ISTR, natural downgradient movement of the warm gw plume, aiding in the biodegradation of dissolved phase in that diffuse downgradient area. Like the first two examples, this too can be Supplemented with electron donor injections (lactate EOS HRC etc), bioaugmentation injections in downgradient area as needed. Additional engineering such as a Warm-water recirculation system may increase duration and distribution of the warmed water plume, or a downgradient barrier wall. To prevent further down gradient mobilization of dissolved contaminant mass, while helping retain warm water through the existing plume. ERH, TCD and SEE are all effective thermal technologies for this option.

For advantages of each of these approaches, check out the webinar recording.

Using Molecular Biological Tools to Monitor and Augment an ISTR Project

Having and selecting the approaches to combine biodegredation and ISTR is the first step, closely followed by having the right tools for proper monitoring and planning your project. When combined with chemical and geochemical groundwater monitoring programs, these analyses really provide the ability to evaluate the potential for biodegradation of multiple contaminants through a number of anaerobic and aerobic metabolic and co(metabolic) pathways. This in turn provides a comprehensive view of contaminant biodegradation that cannot otherwise be gained from individual analyses. By not just looking at the size and health of a particular microorganismal species but actually simultaneously quantifying specific functional genes responsible for aerobic and anaerobic biodegradation, you are able to gain a much needed view of biodegradation potentials, and anticipated degradation trajectories.

Using molecular biological tools (MBTs) such as QuantArray to monitor and inform an ISTR project, provides a comprehensive picture of contaminant biodegradation, including:

- Biodegradation Potential

- Degradation Pathways

- Degradation Trajectory End-product Compounds

MBTs such as QuantArray permit reliable characterization of the site microbial community in terms of community structure, populations present and their biodegradation potential prior to, during and following ISTR. This provides a direct avenue to:

- Assess the need for biostimulation and bioaugmentation

- Evaluate the applicability of heat enhanced bioremediation as a supplemental option to ISTR treatment

Proper monitoring using MBTs can evaluate the need for biostimulation following ISTR as well as evaluate the effectiveness of biostimulation during post-heating thermally enhanced biodegradation. When QuantArray results during site characterization, or following ISTR operations, reveal a lack of dechlorinating bacteria, particularly Dehalococcoides, bioaugmentation may be needed. Following bioaugmentation, QuantArray can be used to confirm increases in dechlorinators as well as to monitor their survival at the site.

Whenever there is the possibility of augmenting or improving an ISTR project with some heat enhanced bio component, you should always monitor at various stages including baseline, during, and post ISTR conditions using the suite of MBTs offered by MI. This enables you to accurately understand and inform what is happening to the bugs living at the site(s), and how to best utilize and augment residual heat from ISTR treatment to maximize the biodegradation potential of those communities of bugs.

In Conclusion

We know that was a lot to unpack. Be sure to check out the recorded webinar for complete details. If you would like more information on our thermal remediation capabilities, you can contact us or request a quote.