The Basics of Using Cone Penetration Testing Rigs for Geotech and HRSC

By: Bill Poupis & Scott Wisher If you’re new to environmental services, you might be trying to understand what cone penetration testing (CPT) is, when to use it, and why. In this blog post, we’ll cover the basics of CPT and its applications.

If you’re new to environmental services, you might be trying to understand what cone penetration testing (CPT) is, when to use it, and why. In this blog post, we’ll cover the basics of CPT and its applications.

What is Cone Penetration Testing (CPT)?

CPT is a method of collecting in situ data to determine soil type. It involves pushing a cone-shaped probe into the subsurface and recording data at specified intervals to measure resistance and friction. This data helps identify the soil's characteristics and properties.

Can CPT Provide Other Types of Data?

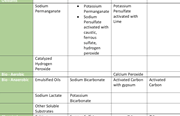

While CPT specifically refers to a type of data collection, the specialized rigs that advance the cone can also deploy other types of probes. These include the WaterlooAPS, MIHPT, and OIP, which are used to collect high resolution site characterization (HRSC) data. This versatility makes CPT rigs valuable for a variety of applications beyond just soil type determination.

When Should You Use Data Collected via CPT?

Geotechnical and Infrastructure Projects

CPT data is often used for geotechnical and infrastructure projects to help engineers determine subsurface stability. This information is crucial for designing foundations, embankments, and other structures.

Environmental Projects

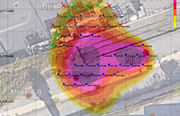

When equipped with HRSC probes, CPT rigs provide detailed information about subsurface contamination. Environmental consultants use this data to assess contamination concentration and extent, guiding them in preparing effective remediation strategies.

Why Choose CPT Over Direct Push Technology (DPT)?

Power and Depth

DPT is a versatile technology, but it can face refusal in difficult subsurface conditions. CPT rigs are generally more powerful and capable of pushing through obstacles, achieving greater depths. This makes CPT a more reliable choice in challenging environments.

Benefits of Using CPT

The benefits of using CPT depend on your project goals and the contractor's capabilities. When you choose a reputable contractor like Cascade, you gain advantages in safety, scheduling, and potential cost savings.

Safety

Cascade’s CORE™ Health and Safety Program ensures our field personnel undergo annual safety training, with constant monitoring to ensure compliance. By engaging Cascade, you work with crews who consistently demonstrate safe on-site practices, eliminating the need to verify another vendor’s safety program.

Scheduling

Working with a single contractor for multiple project components streamlines scheduling, reducing the risk of delays. Poor scheduling can derail a project, causing missed deadlines and cost overruns. Cascade’s integrated approach helps keep projects on track.

Potential Cost Savings

CPT can offer cost savings by combining geotechnical data collection and well development, minimizing the need for extensive drilling programs. In suitable subsurface conditions, CPT data is often sufficient, and the holes created can be used for continued monitoring.

Additionally, some CPT contractors, like Cascade, can provide both CPT and HRSC data from a single borehole. By combining multiple sensors on a single probe advancement, multiple data streams can be collected simultaneously, enhancing efficiency and reducing costs.

Additional Considerations

Choosing the Right Contractor

Selecting a contractor with extensive experience and capabilities in CPT and HRSC is crucial for maximizing the benefits of these technologies. Ensure your contractor can provide comprehensive data collection and analysis services to support your project needs.

Understanding Project Requirements

Clearly define your project goals and requirements to ensure the CPT and HRSC data collected aligns with your objectives. Work closely with your contractor to design a data collection strategy that meets your specific needs.

Conclusion

This blog post provides an overview of CPT and its applications. CPT is a valuable tool for geotechnical and environmental projects, offering reliable data collection and analysis capabilities. If you’re ready to use this technology, request a quote from a trusted contractor like Cascade to ensure your project’s success.

ABOUT THE AUTHORS

Bill Poupis

Sr. Vice President, Drilling Services

[email protected]

Bill Poupis is the Senior Vice President of Operations for the California and Northeast regions. He is a geologist and drilling expert who has worked in the industry for nearly 40 years, and ensures his clients have the right people and technologies on every project. Bill oversees more than 200 employees across six locations, and leads them in performing safe and high quality work that hits project benchmarks and budgets.

Over the course of his career, Bill has provided drilling and related services for environmental, geotechnical, geothermal and oil and gas applications. He spent years perfecting technology for drilling and installing horizontal wells for oil production and, later, for environmental applications.

In his current role, Bill helps clients and junior environmental services professionals better understand drilling best practices, technologies, and applications. He shares his subject matter expertise in Cascade webinars and blog posts (like this one), as well as with clients who are facing drilling obstacles.

Bill’s ability to reimagine existing equipment for new purposes and work creatively on difficult projects makes him an ideal partner for clients facing challenging site conditions.

Scott Wisher

Sr. Vice President, Remediation Services

[email protected]

Scott Wisher is the Senior Vice President of Operations, Remediation Services at Cascade Environmental. He is a professional geologist with more than 18 years of project and business management experience in the consulting and field services industry. During that time, he has implemented remediation system designs using chemical remediation (ISCO, ISCR, bioremediation) and mechanical remediation (AS, SVE) on hundreds of projects throughout the United States. He is also experienced in the effective utilization of high-resolution site characterization for remediation design.

In his role at Cascade, Scott oversees the remediation services division and is responsible for strategy development, P&L management to support business operations, capital expenditure planning, and financial performance for his division.